MC2 Energy Incoming Inspection of Turbine rotor

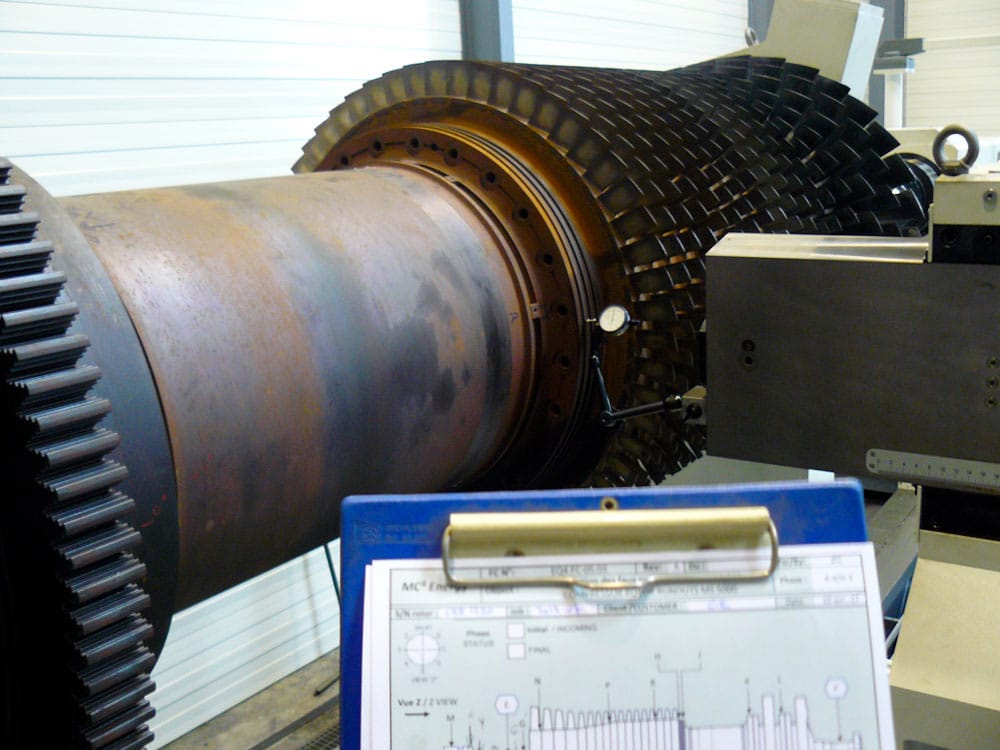

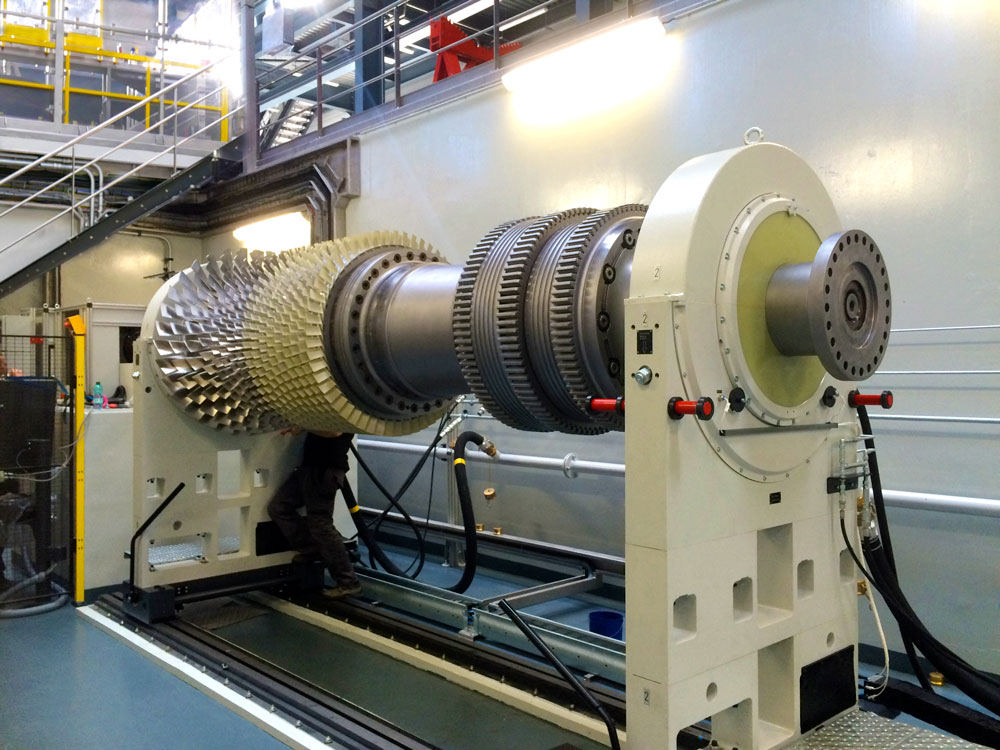

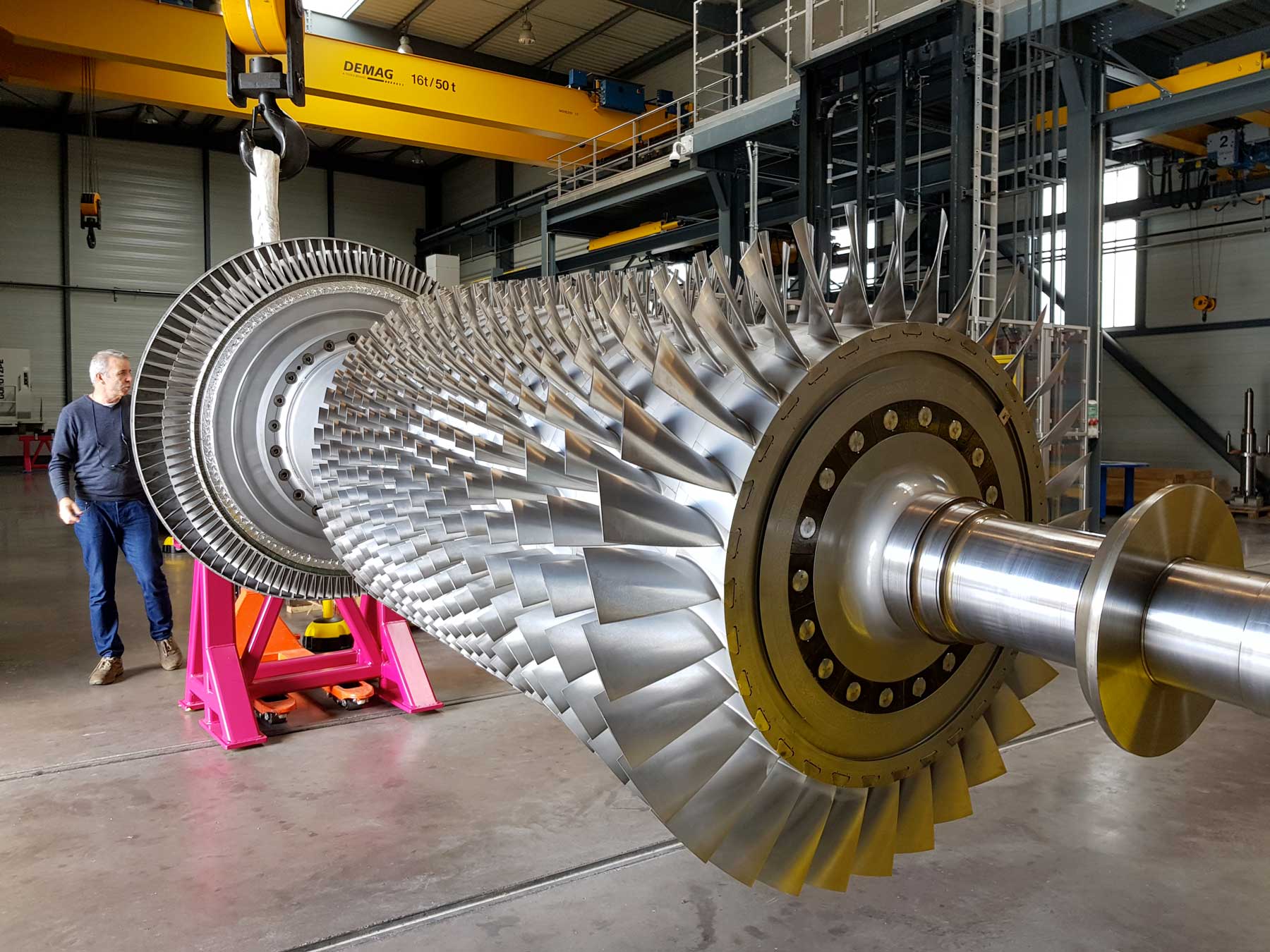

Receipt of rotor

Unloading of rotor in our workshop.

Incoming goods inspection and identification of supplied equipment.

MC2 Energy Initial inspection of turbine rotor

Rotor assessment works

- Visual inspection

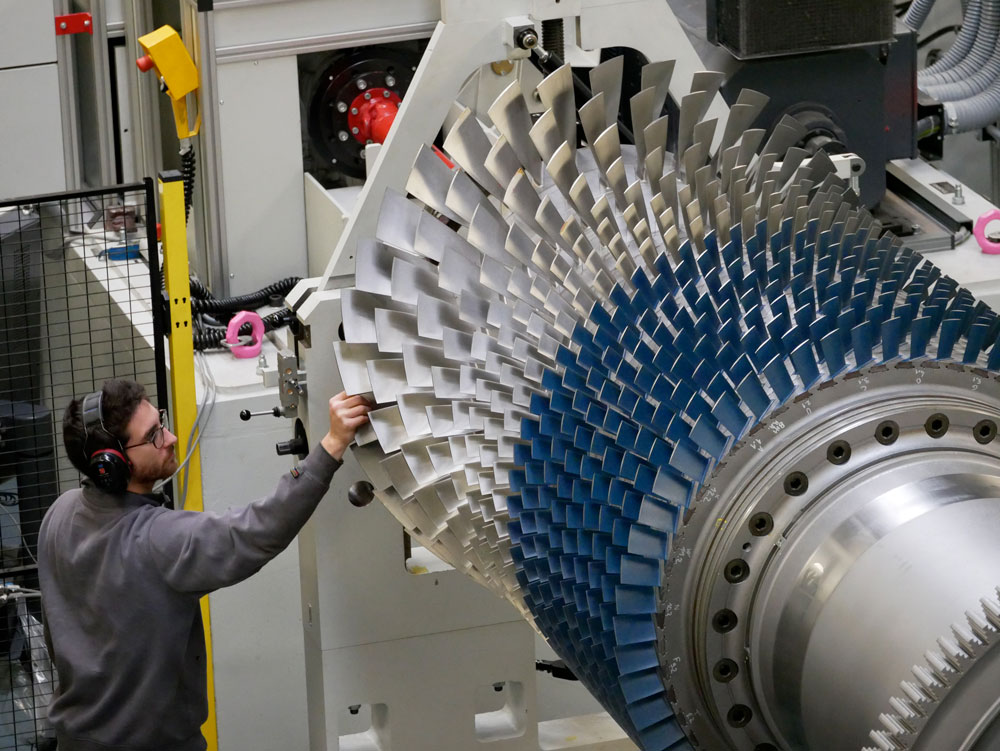

- Turbine blades inspection +

- Cleaning of the assembled rotor with CO2

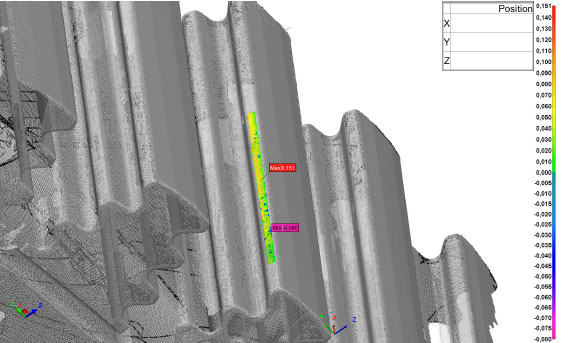

- Inspection of compressor blading +

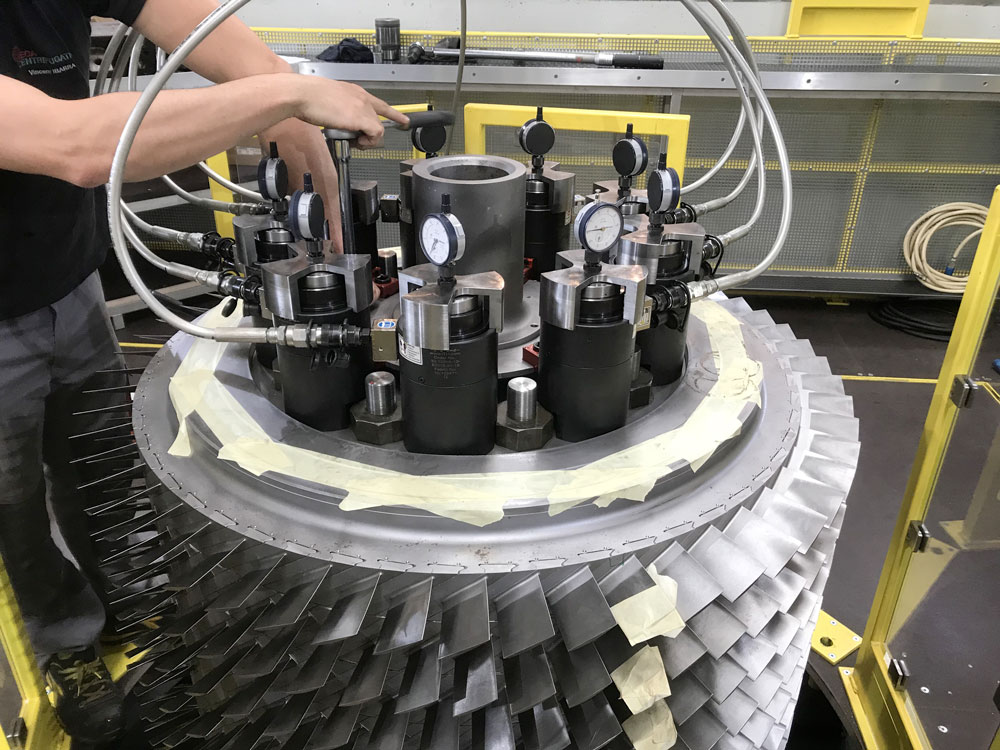

- Ultrasonic inspection of compressor and turbine tie-rods

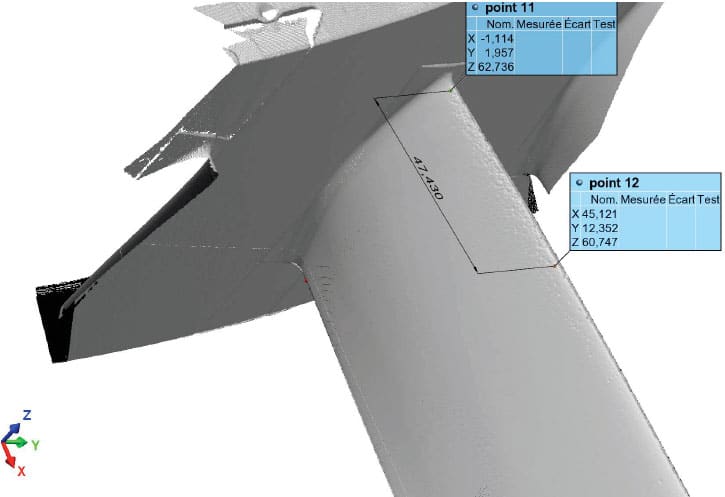

- Dimensional inspection

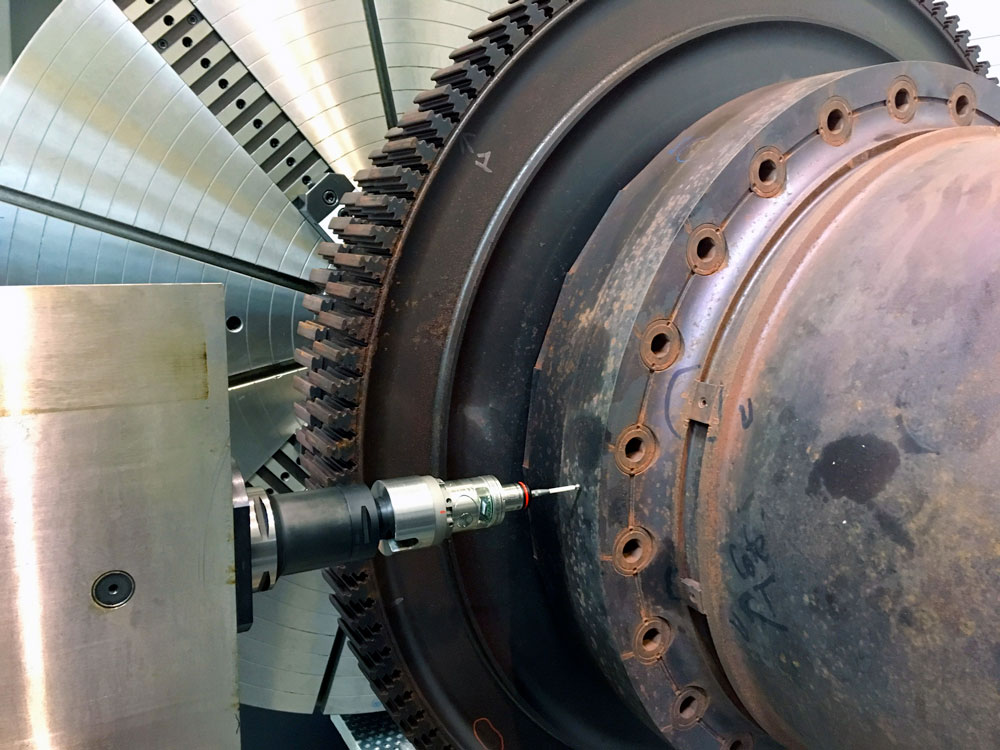

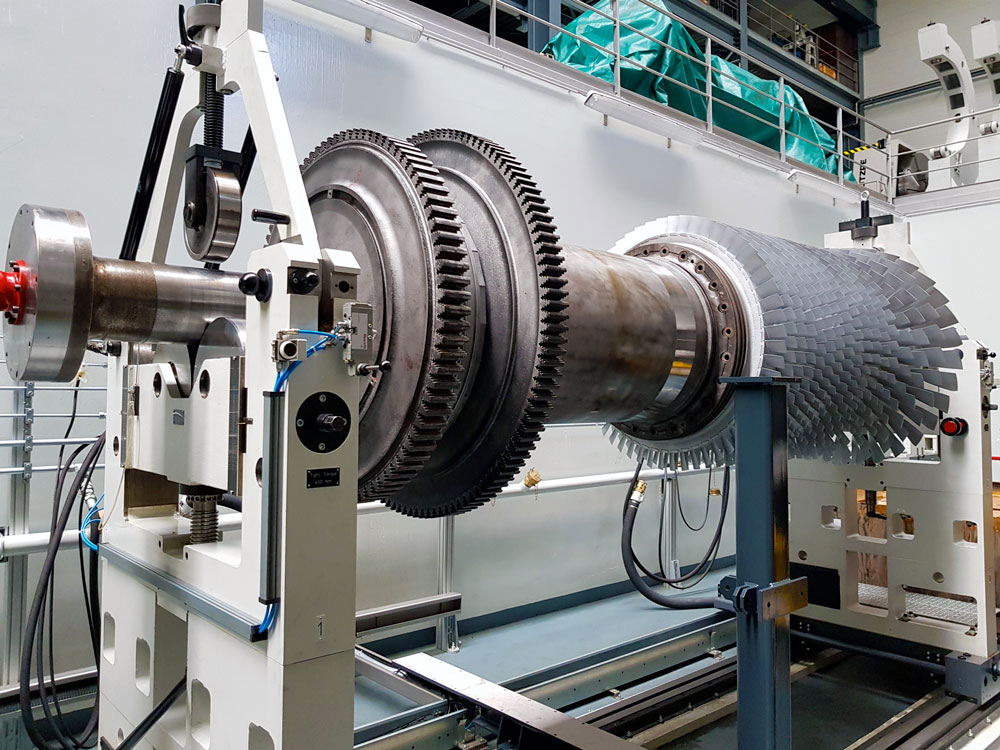

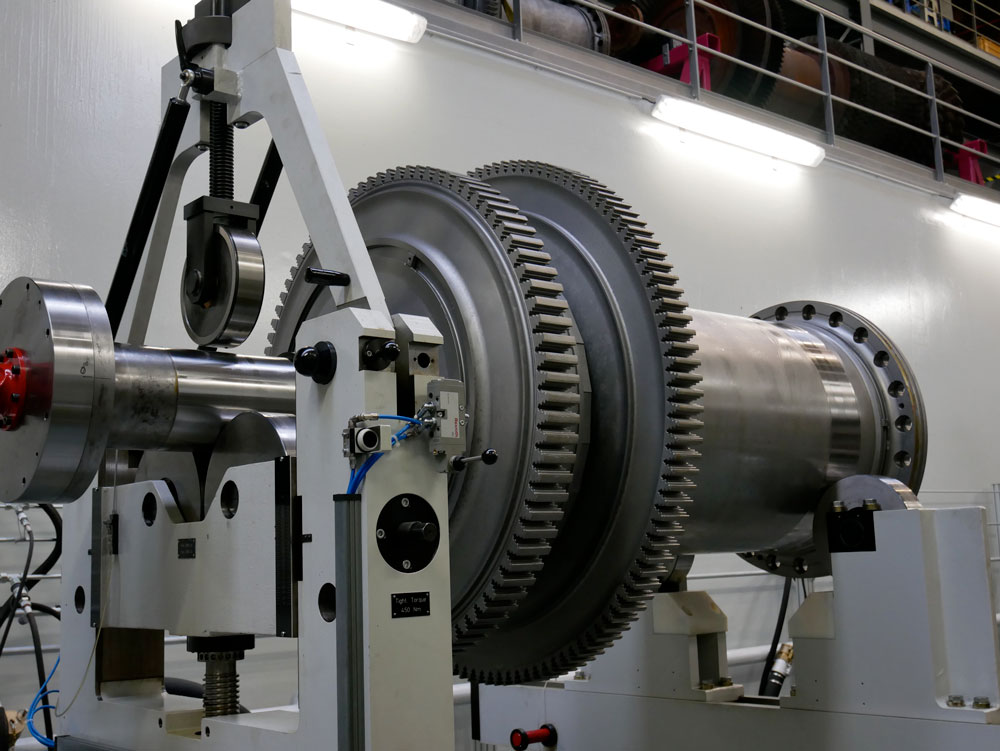

- Runout inspection of rotor on horizontal lathe

- Unbalance verification on balancing machine HM70

MC2 Energy Initial inspection of turbine rotor

Report and Recommendations

This report will be submitted for approval prior to commencing any repair work.

It will entail our experts’ advice regarding the necessary scope of repair as well as suggested improvements on your equipment.

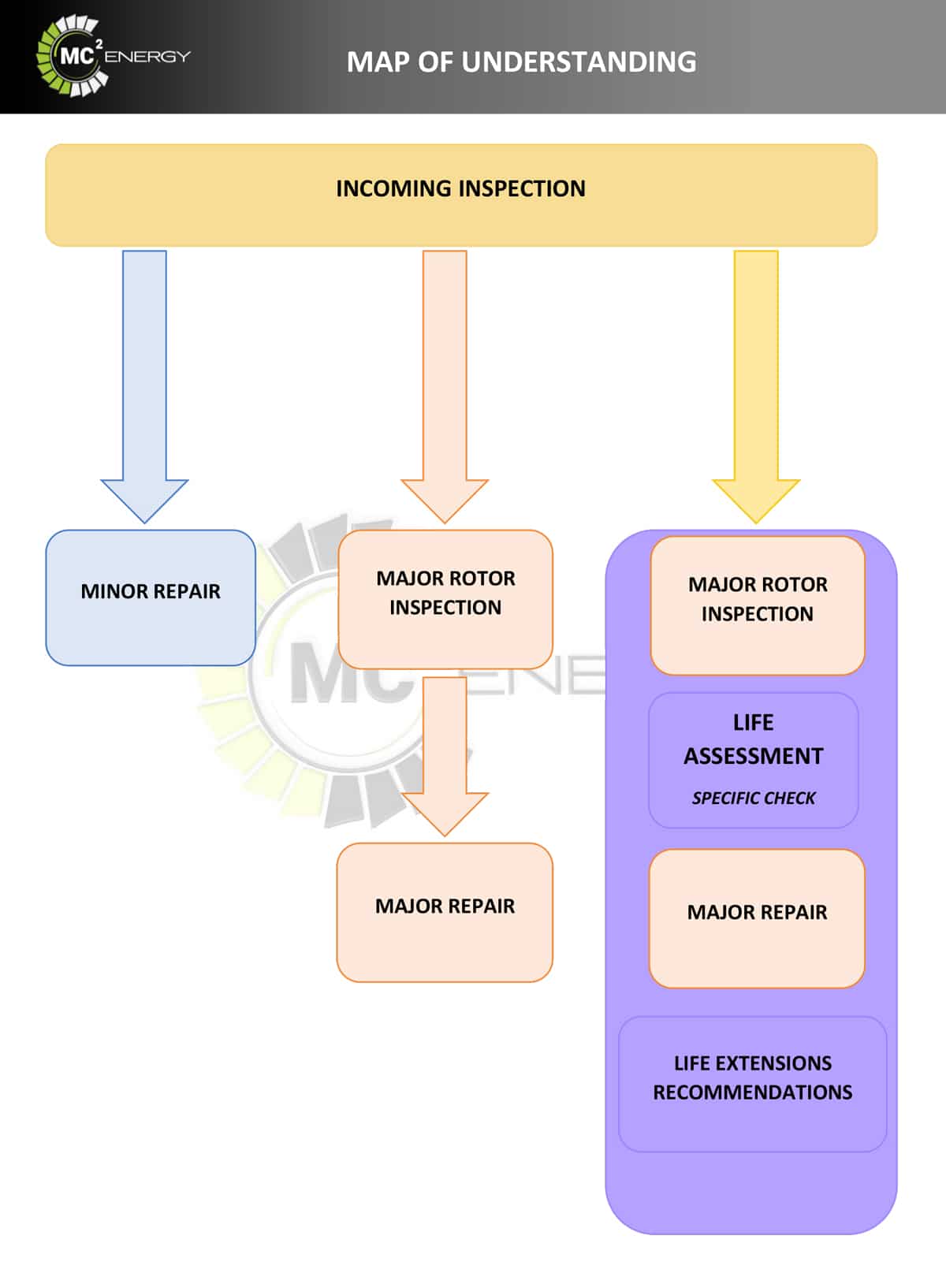

Resulting from the initial inspection we recommend either “minor” or “major” level of work.

We can provide you with our detailed repair offer upon request.

MC2 Energy Minor Repair works

The assessment report issued during the initial inspection determines the level of rotor repair.

Two specific levels of repair are possible, either “Minor” or “Major”.

Only the major repair level will require a second assessment phase.

“Minor” Repair works

Without de-stacking the rotor we can propose the following works :

- Seal repair

- Shaft journal repair

- Correct excessive rocking of the turbine blades

- Dynamic balancing of the rotor assembly

- Final inspection

- Packaging and long-term conservation.

- Repair report writing and issuing

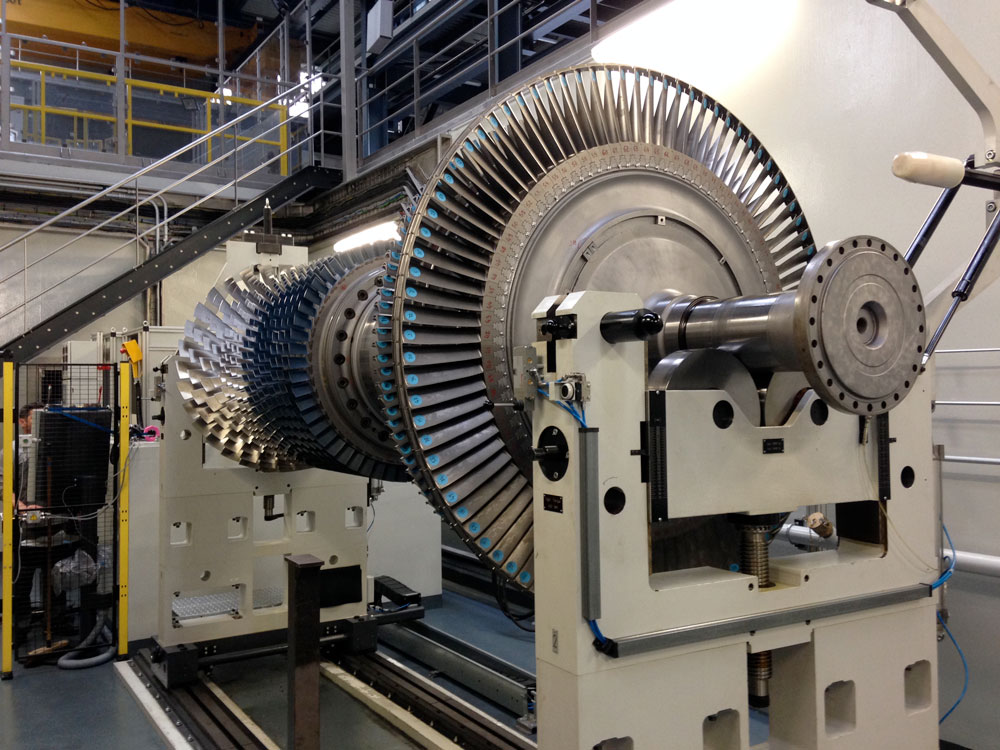

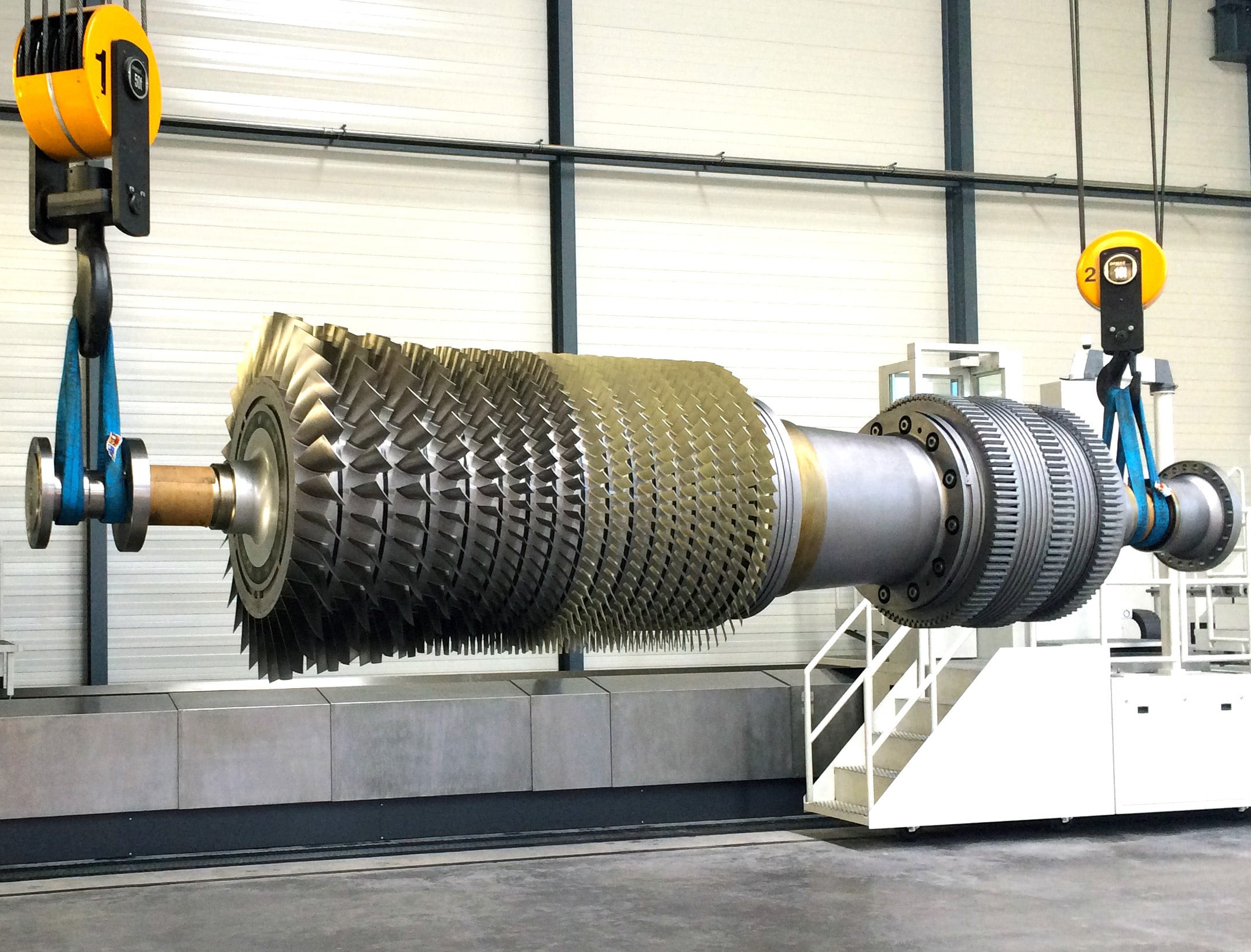

MC2 Energy Major Repair works

“Major” Repair works

Assessment phase 2

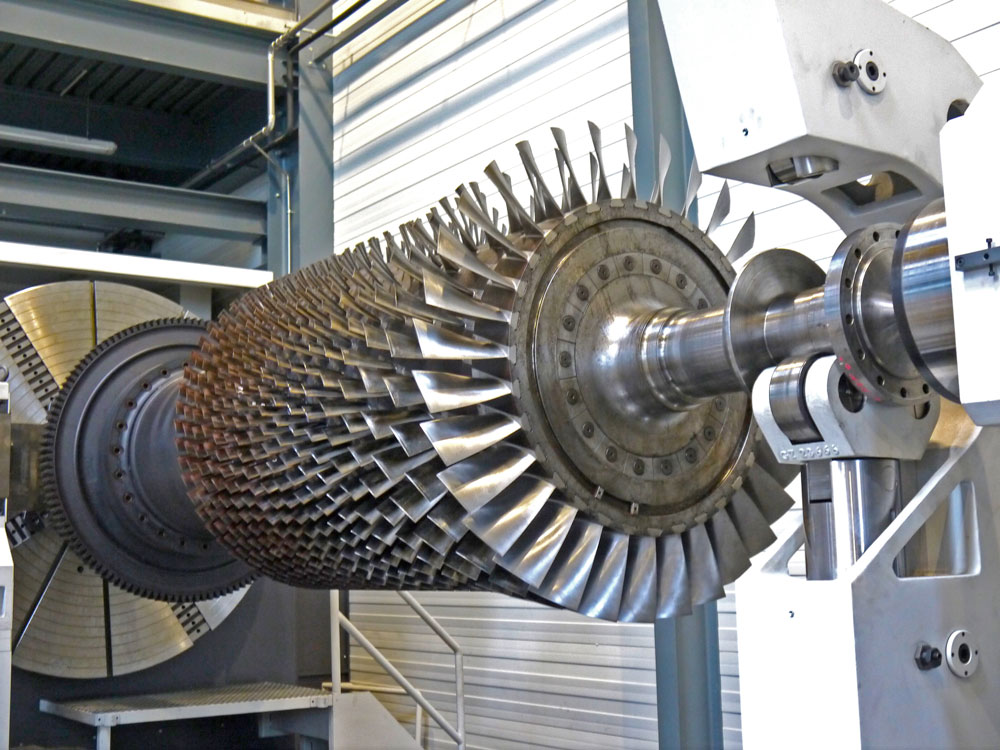

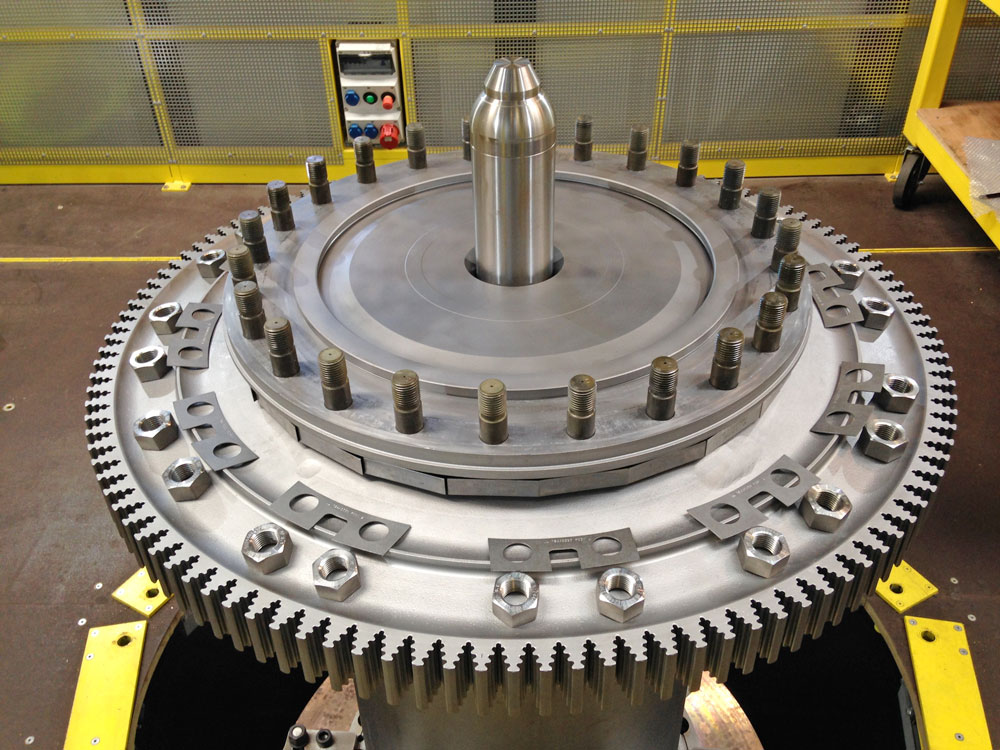

- Tilting the rotor in vertical position

- Uncoupling of turbine and compressor rotor

- Dimensional and run out inspection of compressor rotor

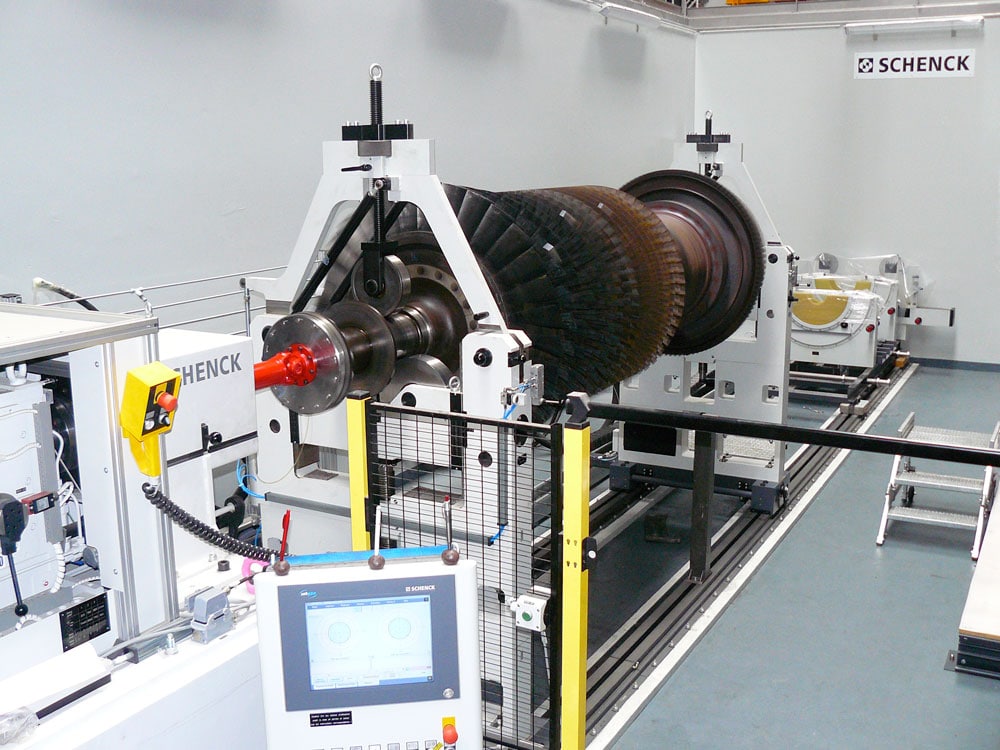

- Unbalance verification of turbine rotor on balancing machine HM70

- Dimensional and run out inspection of compressor rotor

- Unbalance verification of compressor rotor on balancing machine HM70

- De-stacking of compressor rotor

- De-stacking of turbine rotor

- Turbine and compressor rotor component inspection

- Assessment report issued to client for approval prior to execution of major repair level of work

Repair works

- Reassembly of rotor components

- Balancing +

- Final inspection.

- Packaging and long-term conservation.

- Prepare and issue repair report.

Our quality of work is ensured while maintaining the agreed delivery time by our technical capabilities and our staff who will prepare our best offer and give their advice throughout the project.

MC2 Energy Turbine improvments

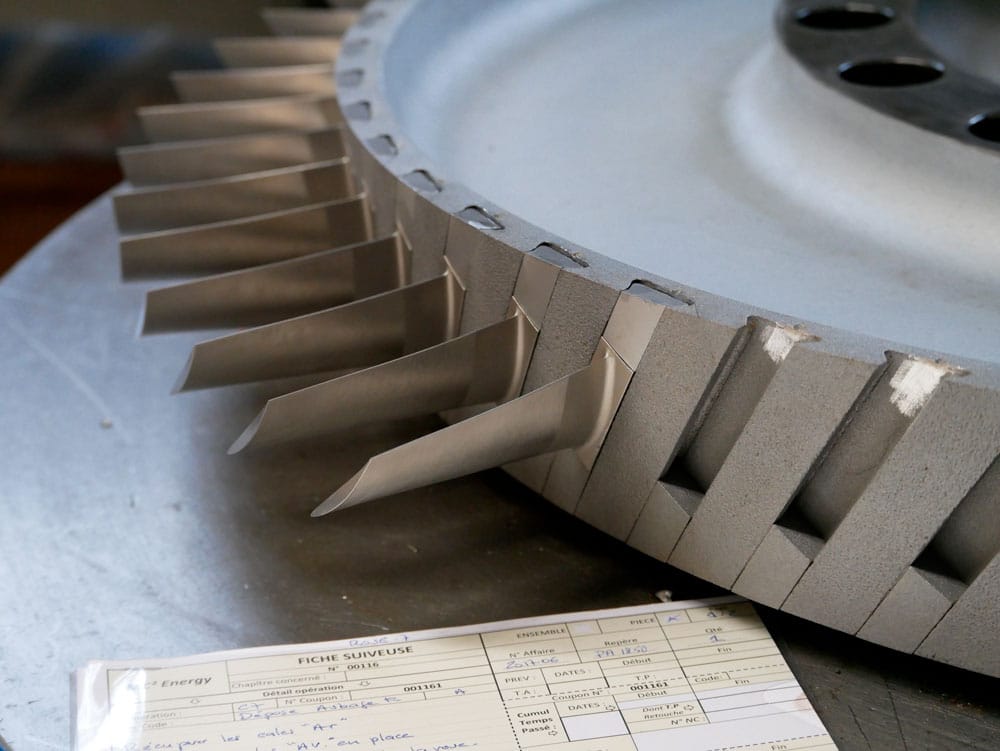

Turbine discs Frame 5/6/9

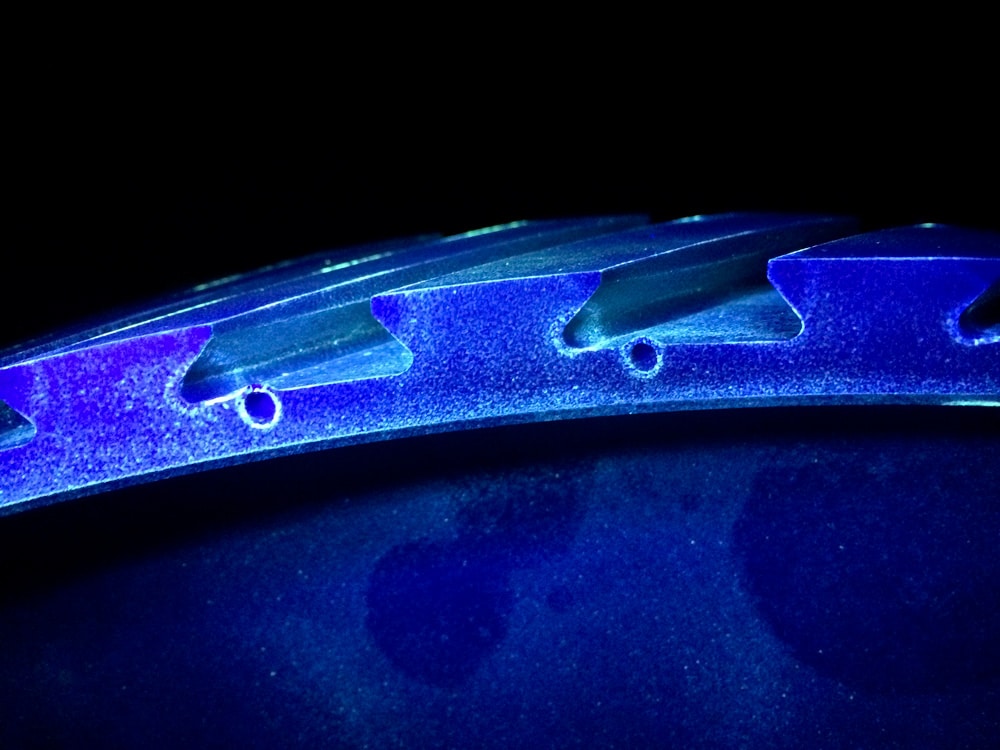

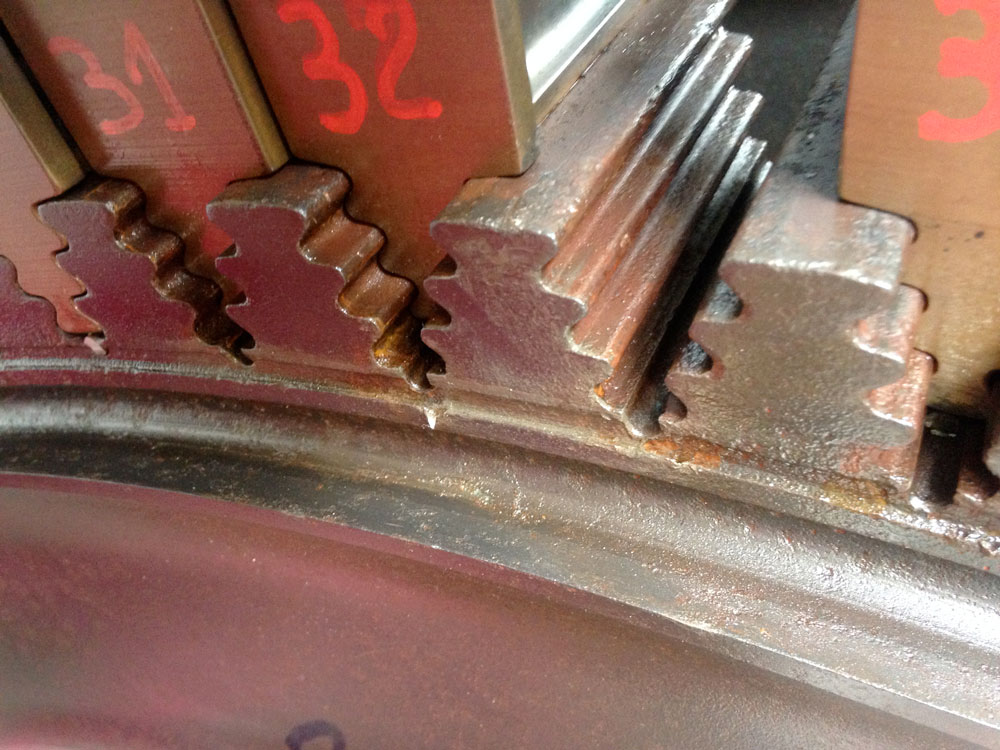

A prolonged outage or stand still period of a gas turbine may cause abnormal occurrence of corrosion on the active and inactive faces of the fir tree root.

After restarting the machine, rust will liberate and will behave like an abrasive material increasing the wear of critical areas.

This will result in excessive clearance between a blade and its slot in the disc which could drive out the sealing pins, rupture the locking pin or breach of the turbine blade or fir tree root.

Turbine blading clearance reduction

Our repair procedure to reduce turbine blading clearance offers an interesting alternative for high cost replacement of a complete turbine row.

MC2 Energy Compressor improvments

Compressor section

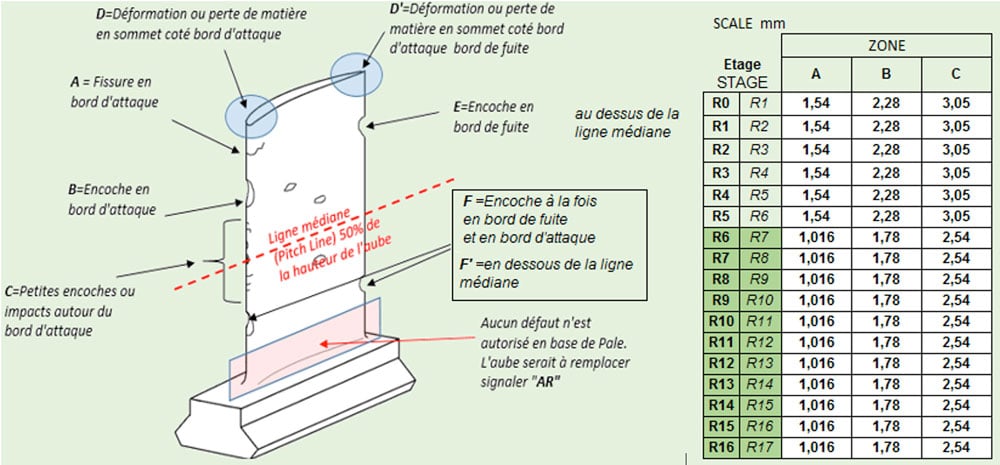

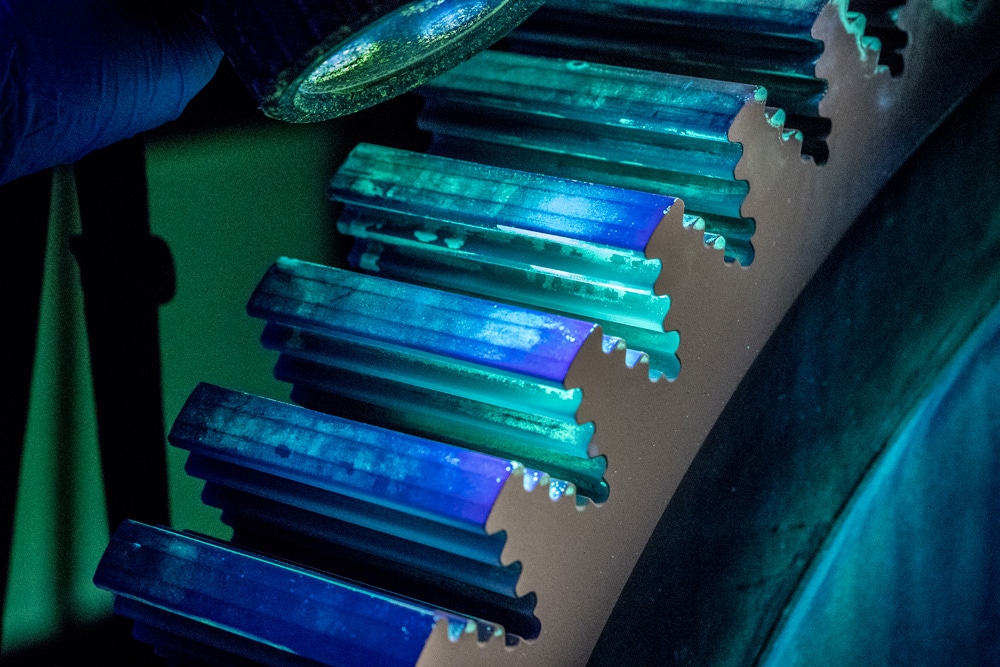

The compressor part generally experiences the following problems:

- Condensation

- Saline air/ Chloride (corrosive environment)

- Air with abrasive particles ( silica, dust etc…)

This phenomenon will cause appearance of corrosion and erosion which consequently causes pitting and profile damage.

Consequences for compressor blading :

The combination « corrosive pitting and fatigue » linked to the operating cycles of the compressor (high vibration frequencies of the blades) weaken the compressor blades and increase the risk of a failure.

Consequences for the compressor discs :

Weakening of the discs, and clogging of rust in the inter-disc areas.

Unbalance du to significant rust deposit.

Compressor blading

MC2 Energy provides advice on the configuration of the compressor blading replacement (rotor and stator).

Examples : type of material, type of coating, design.

The compressor blades supplied by MC2 Energy are latest design which meet the OEM standards and market requirements.

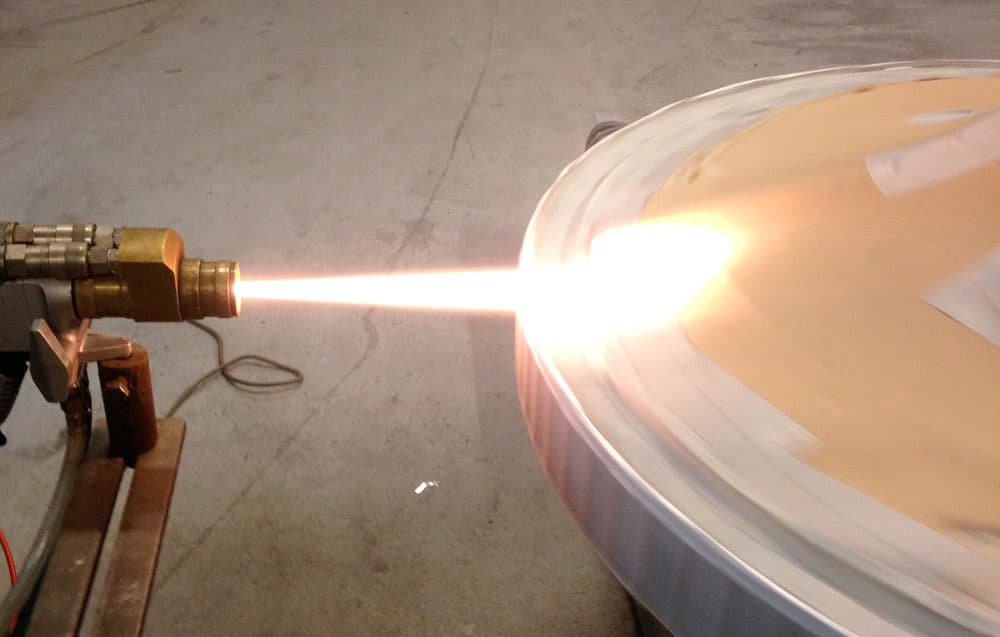

Compressor discs

To increase rotor component lifetime we propose to apply a coating on the compressor disc areas which are prone to corrosion (web area, outer diameter, dovetail).

MC2 Energy Life cycle evaluation

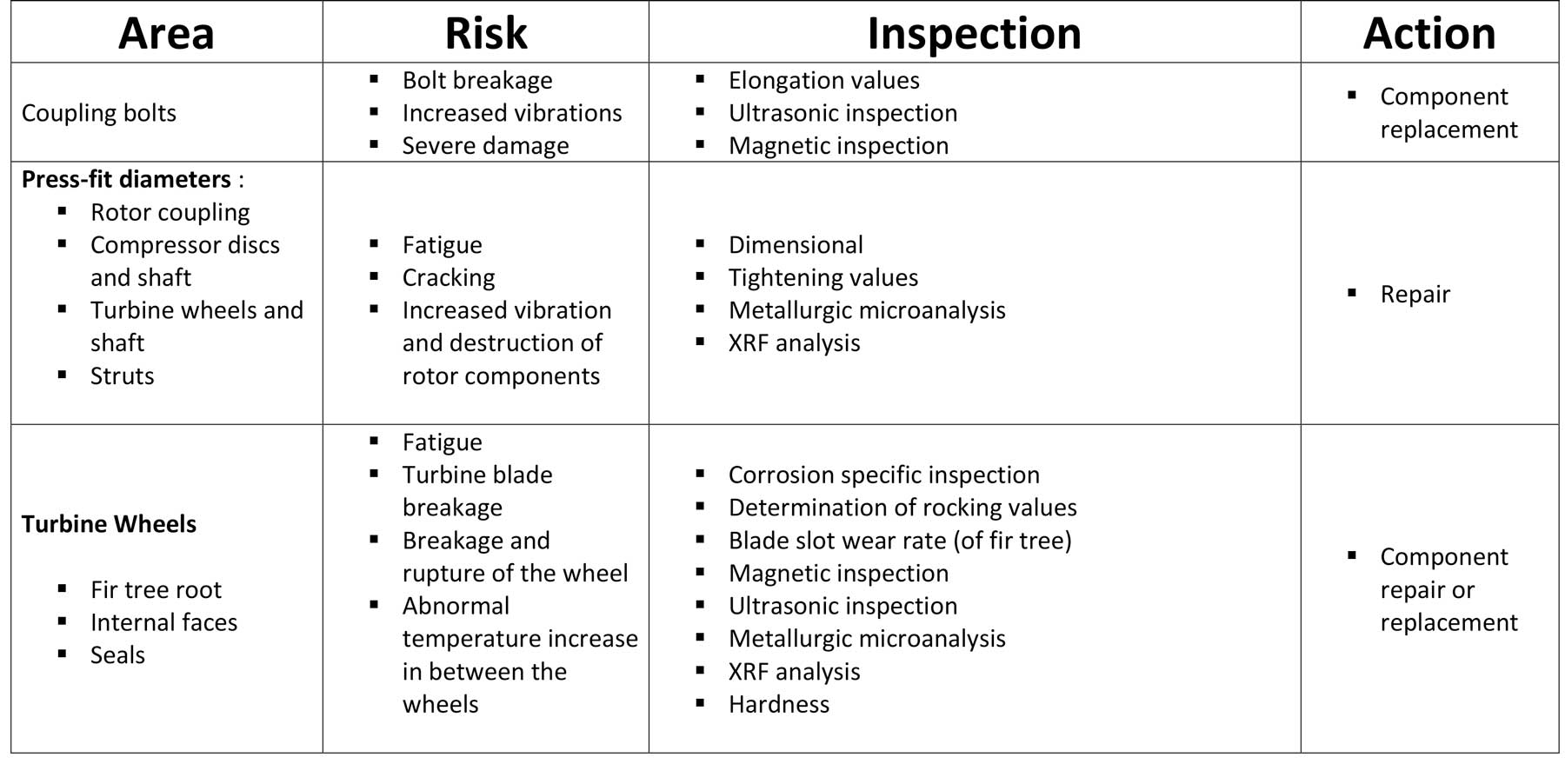

Possible consequences of not respecting the repair procedures or life cycle evaluation of GE type rotors.

In case of a major breakdown repair or life time assessment of GE rotor types the history of the rotor or partial assessment alone are not enough to determine whether the rotor should be put into operation or not.

Inspection of particular major components of a GE type gas turbine rotor can only be executed under certain conditions.

De-stacking will be necessary to reach well-defined areas and execute the following important inspections :

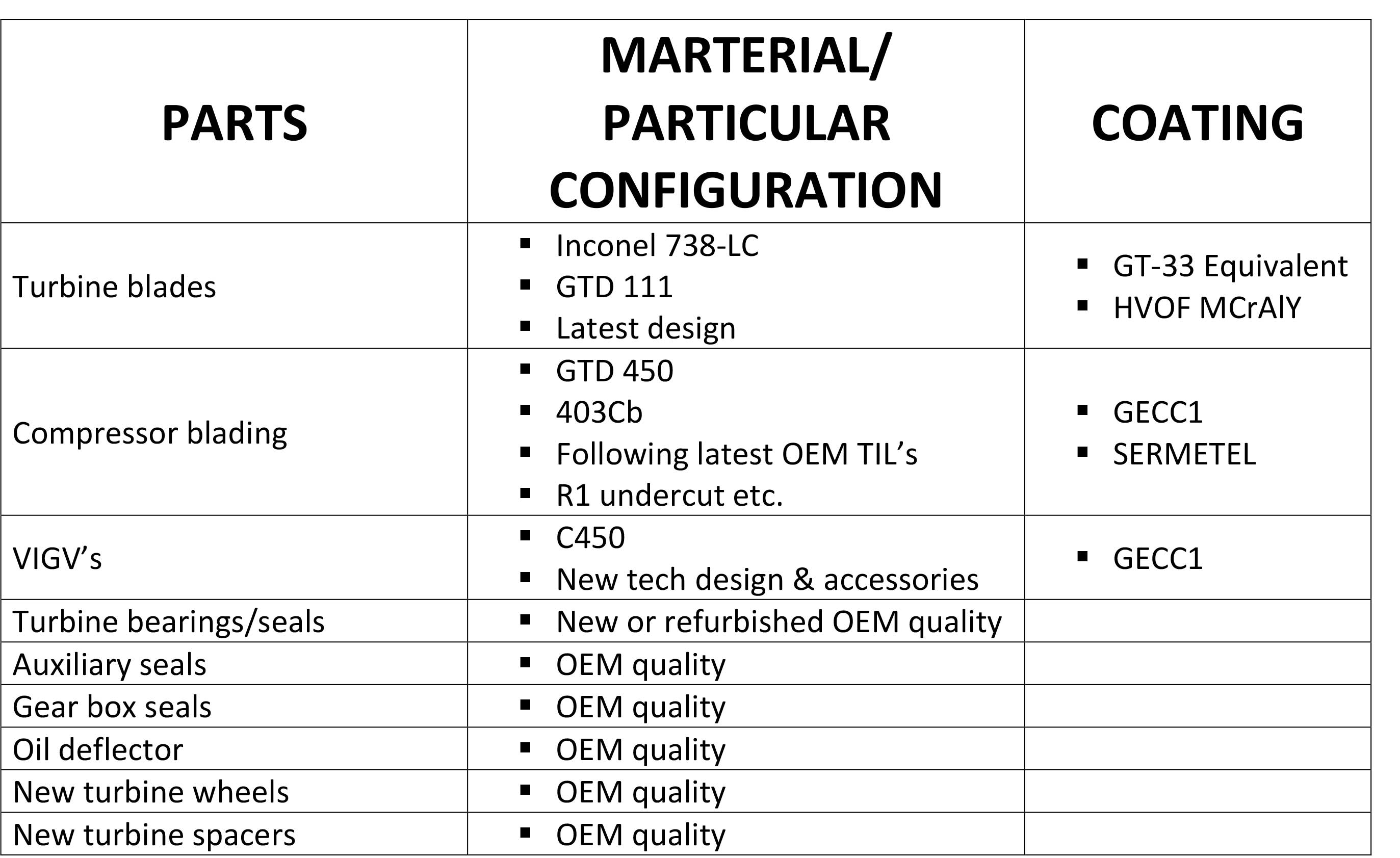

MC2 Energy Spare parts

We recognize the importance of the quality of spare parts installed in your machines.

The parts that we supply to you with the best lead time are latest design, meeting the requirements of your equipment.

The design, the type of material or coating will have a major impact on the reliability of your machine.

MC2 Energy proposes components most suitable for your machine.

MC2 Energy Spare parts

Second hand rotors available and guaranteed by MC2 ENERGY

Other rotors on request (MS 3002/5002/9000).